036EPU-T3122A2G

Loose Tube Circuit Integrity Indoor/Outdoor Cable 3x12 E9 SMF-28e+® ITU G652.D LT 2.0, Cca, s1b, d1, a1

General Specifications

| Product Number | 036EPU-T3122A2G |

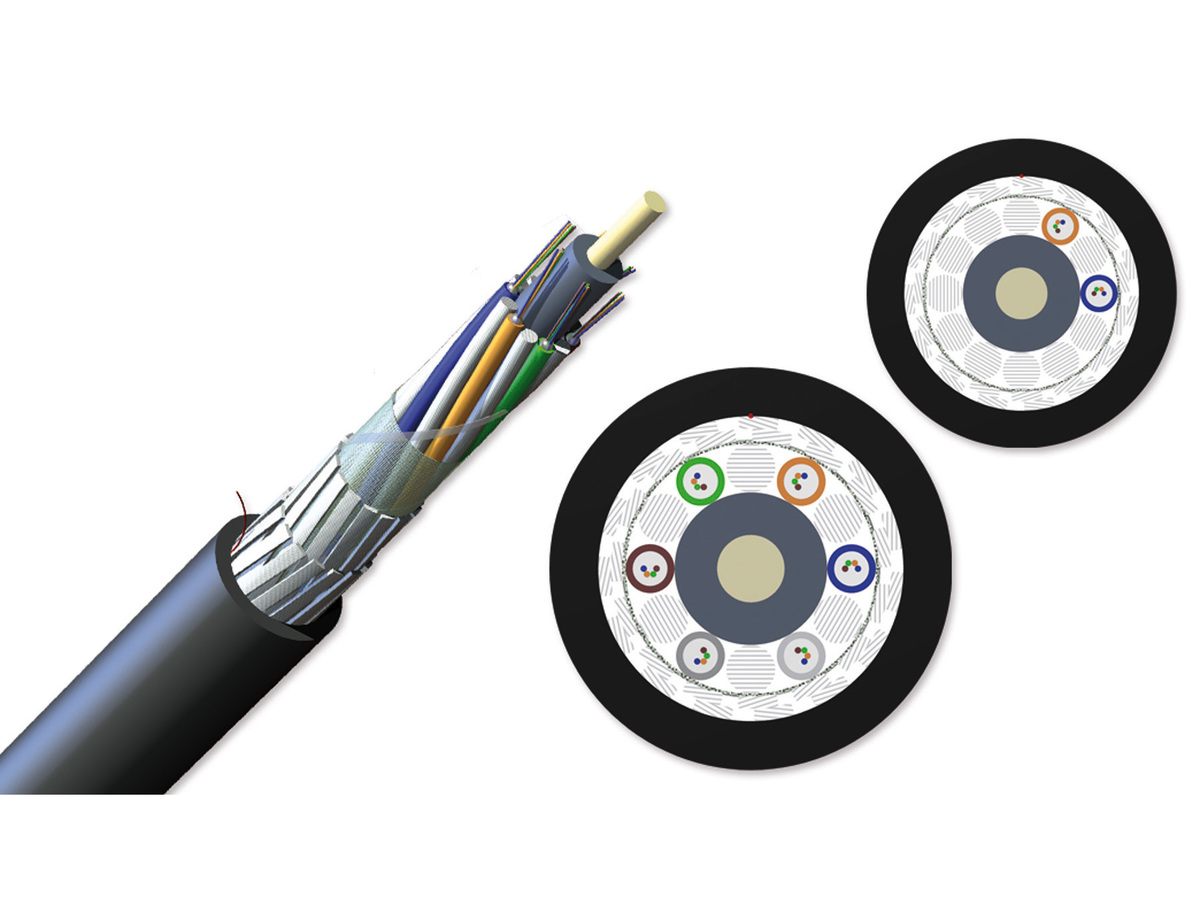

| Cable Type | Loose Tube |

| Environment | Indoor/Outdoor |

| Product Type | Dielectric armor |

| Fiber Category | Single-mode (OS2) |

| Flame Rating | LSZH/FRNC |

| Coding according to EN 60794-1-1 (DIN VDE 0888-100-1) | U-DQ(ZN)BH |

| Application | Duct, General purpose, Horizontal, Vertical Riser |

| Cable geometry | Round |

Standards

| Fiber Standards | TIA/EIA-492CAAB, IEC 60793-2-50 Type B1.3, ITU-T G.652.D, ISO/IEC 11801 Ed.2.2 |

| Reaction to Fire | Cca, s2, d1, a1 |

| RoHS | Free of hazardous substances according to RoHS 2011/65/EU |

| Waterblocking | IEC 60794-1-22 Method F5B |

| Flame propagation test | Flame retardant according to IEC 60332-1-2 (single cable) and IEC 60332-3-24 (bunch of cables) |

| Reaction to Fire Requirements | Reaction to fire according to EN 50575 and EN 13501-6 |

| Smoke density | Low smoke according to IEC 61034 |

| Halogen content test | Zero Halogen according to IEC 60754-1 |

| Level of corrosion | Non-corrosive according to IEC 60754-2 |

| Circuit Integrity | IEC 60331-25 (90 min @ 750 °C) |

Environmental Conditions

| Temperature Range, Installation | -5 °C to 50 °C (23 °F to 122 °F ) |

| Temperature Range, Operation | -30 °C to 70 °C (-22 °F to 158 °F ) |

| Temperature Range, Storage | -40 °C to 70 °C (-40 °F to 158 °F ) |

Cable Design

| Cable Marking | Meter - Handset - CE 17 EN 50575 Cca-s2, d1, a1 - Sine - CORNING - Fiber Optic Cable - Year - U-DQ(ZN)BH 36 E9 LT 2.0 LSZH(TM)/FRNC |

| Central Element | Dielectric |

| Fiber Count | 36 |

| Number of Ripcords | 1 |

| Outer Jacket Color | Black |

| Outer Jacket Material | Flame-retardant, non-corrosive/low-smoke, zero-halogen (FRNC/LSZH) material |

| Outer Jacket Nominal Thickness | 1.95 mm |

| Buffer Tube Color | Blue, Orange, Green |

| Buffer Tube Diameter | 1.95 mm |

| Central Element Diameter | 6.1 mm |

| Number of Active Tubes | 3 |

| Number of Filling Elements | 3 |

| Number of Glass Yarns Filling Elements | 6 |

| Number of Tube Positions | 6 |

| Tape | Mica tape |

| Tensile Strength Elements and/or Armoring | Laminated swelling glass yarn armor |

| Fiber Coloring | Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua |

| Fibers per Tube | 12 |

| Color Code Standards | Telcordia |

Mechanical Specifications

| Crush Resistance | 2000 N/10 cm |

| Max. Tensile Strength for Installation | 5000 N |

| Min. Bend Radius Installation | 284 mm |

| Min. Bend Radius Operation | 245 mm |

| Nominal Outer Diameter | 16.2 mm |

Optical Characteristics

| Fiber Code | E |

| Performance Option Code | 22 |

| Fiber Category | OS2 |

| Fiber Type | Single-mode (OS2) / 250 µm |

| Fiber Name | Single-mode (OS2) |

| Maximum Attenuation | 0.36 dB/km / 0.36 dB/km / 0.22 dB/km |

| Wavelengths | 1310 nm / 1383 nm / 1550 nm |

| Fiber Compliance | ITU-T G.652.D |

| Fiber Core Diameter | 8.2 µm |

| Cladding diameter | 125 µm |

| Coating diameter | 242 µm |

| Dispersion @ 1550 nm | ≤ 18 [ps/(nm*km)] |

| Dispersion @ 1625 nm | ≤ 22 [ps/(nm*km)] |

| Cable cutoff wavelength | 1260 nm |

| Mode-Field Diameter at 1310 nm | 9.2 µm |

| Mode-Field Diameter at 1550 nm | 10.4 µm |

| PMD Link Design Value | ≤ 0.06 ps/√km |

| PMD maximum individual fiber | ≤ 0.1 ps/√km |

Dimensions

| Cable Weight | 270 kg/km |

| Max. cable length per reel/drum | 6000 m |

Circuit integrity technology

Tunnel and secured areas applications

All-dielectric construction

Requires no grounding or bonding

UV- and microbe-resistant

Can be installed in ducts or conduits

Dry core

Allows efficient and craft-friendly cable preparation in outdoor or indoor/outdoor applications

Laminated glass yarns

Improved rodent resistance

Fibres/buffer tubes colour coded to Telcordia-Bellcore

Easy identification of the individual tubes and fibres

SZ-stranded, loose tube design

Isolates fibers from installation and environmental rigors and facilitates mid-span access

Flame retardant

LSZH/FRNC