BMCZQZ-13041R20

RocketRibbon® Indoor/Outdoor, Riser-LSZH 6912F, SMF-28 Ultra 200 µm Fiber, Single-mode, Cca, s1, d1, a1

General Specifications

| Product Number | BMCZQZ-13041R20 |

| Cable Type | Ribbon |

| Environment | Indoor/Outdoor |

| Product Type | Dielectric |

| Fiber Category | SMF-28® Ultra |

| Flame Rating | Riser (OFNR-LS) |

| Application | General purpose, Horizontal, Vertical Riser |

| Cable geometry | Round |

Standards

| Reaction to Fire | Cca, s1, d1, a1 |

| RoHS | Free of hazardous substances according to RoHS 2011/65/EU |

| Approvals and Listings | National Electrical Code® (NEC®) OFNR-LS, CSA FT-4 |

| Design and Test Criteria | ANSI/ICEA S-104-696 |

| Flame Test Method | UL-1666 (for riser and general building applications), UL-1685 (National Electrical Code® (NEC®) OFN-LS) |

| Reaction to Fire Requirements | Reaction to fire according to EN 50575 and EN 13501-6 |

Environmental Conditions

| Temperature Range, Installation | 10 °C to 60 °C (50 °F to 140 °F ) |

| Temperature Range, Operation | -40 °C to 70 °C (-40 °F to 158 °F ) |

| Temperature Range, Storage | -40 °C to 70 °C (-40 °F to 158 °F ) |

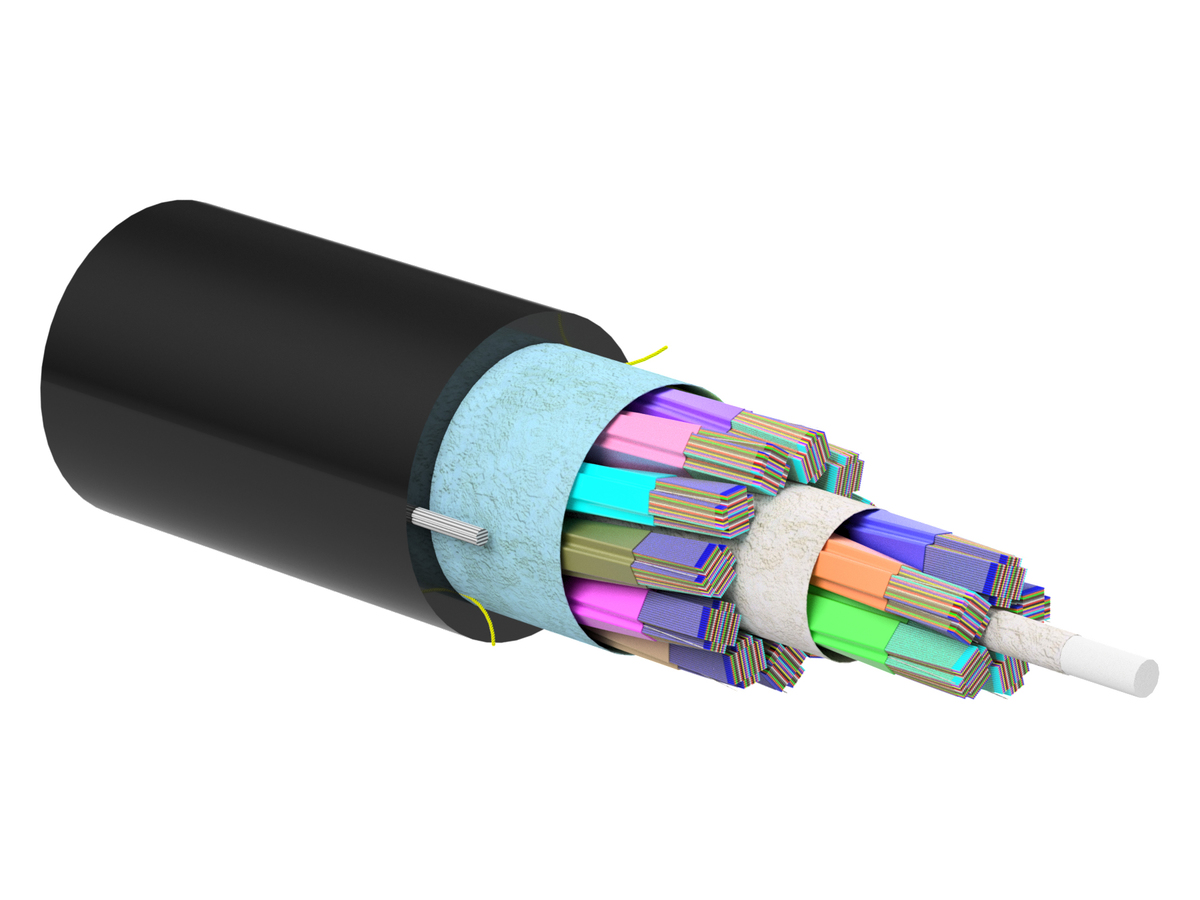

Cable Design

| Fiber Count | 6912 |

| Fiber Coloring | Blue, Orange, Green, Brown, Slate, White, Red, Black, Yellow, Violet, Rose, Aqua |

| Outer Jacket Color | Black |

| Outer Jacket Material | Polyethylene (PE) |

| Tensile Strength Elements and/or Armoring - Layer 1 | Dielectric strength members |

| Number of Subunits | 16 |

| Fibers per Ribbon | 432 |

Mechanical Specifications

| Min. Bend Radius Installation | 580 mm (22.83 in) |

| Min. Bend Radius Operation | 580 mm (22.83 in) |

| Nominal Outer Diameter | 38.3 mm (1.51 in ) |

Optical Characteristics

| Fiber Code | Z |

| Performance Option Code | 01 |

| Fiber Category | OS2 |

| Fiber Type | Single-mode (OS2) / 250 µm |

| Fiber Name | Bend-Improved Single-mode (OS2) |

| Maximum Attenuation | 0.4 dB/km / 0.4 dB/km / 0.3 dB/km |

| Wavelengths | 1310 nm / 1383 nm / 1550 nm |

| Fiber Compliance | ITU-T G.652.D and ITU-T G.657.A1 |

Dimensions

| Cable Weight | 120.58 kg/km (81.03 lb/1000 ft) |

Flexible, routable subunit eliminates the need for furcation when routing directly into hardware and enabling individual access to each ribbon for efficient management in splice trays

No messy filling or flooding compounds mean elimination of time, labor and risk associated with cleaning ribbons, enabling cleaner work areas, simplified splice preparation and less installer error